Statewide Infrastructure and Facilities

The Oklahoma Photovoltaics Research Institute encompasses several partner groups across the scientific and engineering disciplines at OSU, OU, and TU, and in Oklahoma based industry. Within these individual research groups there are complementary facilities, resources, and infrastructure that are used across the state by the partners to facilitate individual, group, and statewide research programs. A summary of the major resources are listed below:

Undergraduate students Nick Estes, Alison Roeth, and Patrick Vallely performing device analysis in the Photovoltaic Materials and Device Group at the University of Oklahoma.

Optical and Optoelectronic Laboratories: A complete array of experimental tools for the proposed optical and optoelectronic investigations are housed in the laboratories at OU. These experimental capabilities include a Princeton Instruments spectrometer fitted with a Roper Scientific InGaAs linear array (operating between 800 – 1600 nm) and a Princeton Instruments PIXIS-eXcelon silicon CCD (350 – 950 nm). This system is fitted with both UV and IR gratings, producing a total accessible spectral width from 350 nm to 1600 nm. Also included in the laboratory are a Thorlabs HeNe Laser (model HNL210L-JP), a Kimmon Electric HeCd dual-wavelength (325 and 442 nm) laser (model IK552R-F), and a 1064 nm solid state diode laser for optical excitation in both UV and IR spectral regions. The laboratory also includes a Janis Model SHI-4-5 optical closed-cycle cryostat system operating from 4.2 to 300 K for optical spectroscopy.

In addition, there is a Newport quantum efficiency system for internal and external quantum efficiency (EQE) measurements; as well as, photo-modulation, electro-reflectance spectroscopy, and resonant photoluminescence (PL) capabilities. This EQE system, coupled with a Newport class-ABA solar simulator, gives the laboratory full solar cell characterization capability. A Linkam THMS600E micro-cryostat with full temperature control (77 K to 873 K) is also available in this laboratory, which is utilized to investigate carrier transport and parasitic losses in solar cells. A Janis ST-500 superconducting magnet for micro-PL under high magnetic fields is also housed at OU. This system is used to investigate the fundamental nature of localized centers in PV materials at temperatures ranging from 4.2 K to ambient, and magnetic fields from 0 – 7 Tesla.

Solar concentrator (14x) housed at the North Campus of the University of Tulsa.

The University of Tulsa (TU) also houses a full suite of PV characterization tools including a solar simulation, internal quantum efficiency system, and an external concentrator PV system with the ability to test materials and solar cells under 14x concentration in ambient conditions. Several facilities for the investigation of soft materials and nanostructures are also housed in the Departments of Biology and Chemistry at TU. These include a Shimadzu 1800-UV UV-absorption system, a temperature dependent JY6400 Raman/micro-Raman spectrometer, and a Nicolet iS50 Fourier Transform Infrared Spectroscopy (FTIR) system.

Transport and electrical Analysis: TU also houses several complementary instruments for impedance/admittance spectroscopy and capacitance-voltage measurements including a deep level transient spectroscopy system (DLTS) and several A.C. Impedance Analyzer(s). In addition, TU also houses (along with OU) various electrical and electronic equipment for general device characterization and analysis, including, amongst others, A.C. and D.C current-voltage systems and Hall measurement systems.

Ultra-high-vacuum photoemission systems housed in the Department of Chemistry at OSU Stillwater.

Materials Characterization Facilities: Microscopy (SEM) facilities are available on the Norman campus of OU at the Samuel Roberts Noble Microscopy Laboratory. This facility includes a 200 kV field-emission JEOL 2010F TEM and a 200 kV analytical JEOL 2000FX TEM. TEM specimen preparation is currently accomplished using mechanical thinning, polishing, and low-temperature ion milling. The dual-beam FIB and SEM will allow specific features to be prepared (thinned) for TEM analysis using the “H-bar” in situ technique. With the upcoming addition of a Kleindiek nanomanipulator we will soon be able to routinely perform in situ lift-out (INLO) preparation of TEM specimens.

The department of Chemistry at OSU Stillwater is home to a custom built ion-pumped UHV chamber capable of AES, UPS and XPS. In addition, a quadrupole mass spectrometer with a 300 amu range is also mounted in this chamber for TPD/TPR studies. A 5-keV ion gun capable of being differentially pumped is utilized for sample cleaning and depth profiling. A custom UHV manipulator provides tilt and two-dimensional motion and allows for heating and cooling of the sample. In addition, a smaller chamber, evacuated by a turbo pump, is connected to this chamber. These facilities are used as part of recent NASA funded work on the role and contribution of hydrogen passivation in dilute nitrides semiconductors for applications in next generation multi-junction solar cells, a program involving faculty from all member institutions.

Amethyst Research Inc., 2.5 MV Van de Graaff accelerator facilities for Ion Beam Analysis, based in Ardmore, OK.

OSU also has several additional pieces of major equipment available for this statewide collaborative research. The list includes a Varian UNITY INOVA 600 NB NMR System, a Varian UNITY INOVA 400 NB NMR System, a Varian 300 MHz Broadband GEMINI 2000 High-Resolution NMR System, a Chemagnetics CMX-300 Solid State NMR Spectrometer, a Perkin Elmer and a Nicolet FTIR and Raman spectrometers, a Cary and a HP UV-Visible spectrometer, a Bruker Advance X-ray powder diffractometer with indexing, crystallite size, search/match, and quantitative analysis capabilities and a Spectro-X-ray fluorescence spectrometer. Finally, a Varian Flame and Graphite Furnace atomic absorption spectrometers and a Malvern HPPS 5001 High Performance Particle Sizer for dynamic light scattering with nanoparticle capabilities are available.

UV and plasma-assisted hydrogenation facilities housed at Amethyst Research Inc. in Ardmore, Oklahoma.

Industrial partner Amethyst Research Inc. based in Ardmore, Oklahoma has partnered several groups around the state on collaborative projects bringing their expertise in materials development and research, with particular specialties in materials compositional and quality analysis. Amethyst’s ion beam facility includes a 2.5 MV Van de Graaff accelerator. Ion beam analysis is a multi-functional tool that can be used to perform a number of material characterization techniques including Rutherford backscattering spectrometry (RBS), ion-channeling, particle-induced x-ray excitation (PIXE), elastic recoil detection analysis (ERDA), and nuclear reaction analysis (NRA).

In particular, the deuterium concentration is evaluated with NRA using 700 keV 3He+-ions, which is the core to Amethyst’s proprietary characterization technique, Amethyst wafer mapping (AWM). Amethyst is currently installing an ion microprobe with a submicron spatial resolution. Amethyst Defect Mitigation (ADM) process is supported by UV-activated hydrogenation system, which includes various in-situ monitors to ensure reproducibility of its process. It includes active heating/cooling of the sample and wafer rotation to ensure irradiation uniformity. It also includes an XPS system. The system from Staib Instruments Inc. consists of an x-ray tube with Mg and Al sources (model RQ 300) and an integrated 5 keV electron gun (for Auger excitation) for XPS/Auger spectroscopy (model DESA 100). A target/system chamber has been designed with non-magnetic 316 stainless steel to avoid any field interference during analysis. It also includes a residual gas analyzer (RGA) for monitoring process gas composition in real time. A UV intensity sensor is set to monitor the photon dose for each process cycle.

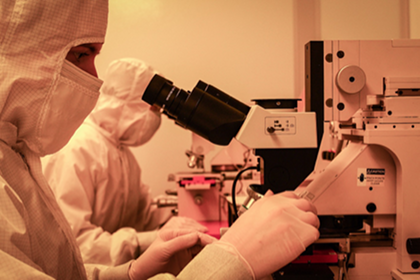

Students at work in the MREC cleanroom facilities on the OU Norman Campus.

Semiconductor Processing Facilities: Solar cell fabrication will be performed in the University Microfabrication Research and Education Center in the Department of Electrical and Computer Engineering at OU. This 3360 square foot class 1000 cleanroom facility contains equipment for photolithography (Karl Suss MJB-3 mask aligner, Laurel Technologies WS-200-4NPP photoresist spinner), wet processing, and several thermal deposition systems for metallization. In addition, the cleanroom also houses chemical vapor deposition and pulsed electron deposition systems for formation of dielectric and insulating layers, and high band gap nitrides and oxide semiconductors, respectively. Several device fabrication facilities are also at TU including spin coating, thermal evaporation systems, and heating systems. The TU group also has an RF sputtering tool, which is useful for the deposition of thin-films and dielectrics. These system have been by several partners to process oxide and solution-based solar cells and devices.

The Cowboy supercomputer cluster. Funded by an NSF MRI grant and housed at OSU Stillwater.

Computation facilities/capabilities: In addition, to a solid suite of experimental resources, the center also has a strong theoretical/computational component with members from OU, OSU, and TU performing density functional theory (DFT) calculations in support of several statewide programs. At OSU, there is sole access to a 120-core GP-GPU cluster that is housed in the Borunda computational lab. This GP-GPU Cluster is a general-purpose cluster outfitted with graphics processing unit consists of ten compute nodes each equipped with the following: Intel Core i7-3930K Sandy Bridge 3.2 GHZ processor (6-cores and 12 MB cache), 1 TB hard drive + 256 GB solid-state HD, 32 GB SDRAM, 1 NVIDIA Tesla C2075 GPU card (448 CUDA cores running at 575 MHz and 6 GB RAM), and 1 NVIDIA GeForce GTX 660 TI GPU card (1344 CUDA cores running at 915 MHz and 3 GB RAM). Each node has two stand-alone GPUs, our cluster has a total of 17,920 CUDA cores optimized for highly parallelized calculations.

OSU's HPCC Facilities are currently composed of `Cowboy' which is equipped with the following: 252 compute nodes (Intel Xeon E5-2620 “Sandy Bridge” hex core 2.0 GHz CPUs), 2 “fat nodes” each with 256 GB RAM and an NVIDIA Tesla C2075 card (the rest is the same configuration as above), 92 TB of globally accessible high-performance disk provided by three shelves of Panasas ActivStor12, Infiniband for message passing, Gigabit Ethernet for I/O, and an ethernet management network, 15 compute nodes (same configuration as above) each with two Xeon Phi cards (64 cores running at 1.30 GHz and with 16GB RAM) available only to the Fennell and Borunda groups at OSU (Condominium Equipment). Institute member Mario Borunda is a Co-PI in an NSF-funded MRI project that will keep the supercomputer up to date for the following five years.

Institute members also have access to the OU Supercomputing Center for Education and Research (OSCER), located on the Norman campus, and the NASA Advanced Supercomputing systems. In 2015, OSCER has been deploying ‘Schooner’, the largest academic supercomputer in Oklahoma history. This Dell cluster supercomputer has a peak speed of 346.9 TFLOPs (trillions of calculations per second) and consists of 499 compute nodes, 10,180 CPU cores, ~23 TB RAM, ~450 TB of globally accessible user storage, and two networks. Computing capacity consists of: PowerEdge R430 compute nodes (servers), 266 × dual Intel Xeon “Haswell” E5-2650v3 10-core 2.3 GHz, 32 GB RAM (all owned by OSCER), PowerEdge R730 compute/accelerator-capable nodes, 4 × dual Haswell E5-2650v3 10-core 2.3 GHz, 32 GB RAM, dual NVIDIA K20M accelerator cards (3 OSCER, 1 condominium), 12 × dual Haswell E5-2650v3 10-core 2.3 GHz, 32 GB RAM, dual Intel Xeon Phi MIC 31S1P accelerator cards (all OSCER), 13 × dual Haswell E5-2650v3 10-core 2.3 GHz, 32 GB RAM, no accelerator cards (all OSCER), and 5 × dual Haswell E5-2670v3 12-core 2.3 GHz, 64 GB RAM, no accelerator cards (all OSCER). Storage consists of both a large scale, high performance parallel filesystem and servers full of disk drives (high performance parallel filesystem, global user-accessible: DataDirect Networks Exascaler SFX7700X, 70 SATA 6 TB disk drives, ~305 TB useable) and lower performance servers full of disk drives, global user-accessibe (~150 TB useable). The nodes are networked with Infiniband and Ethernet.